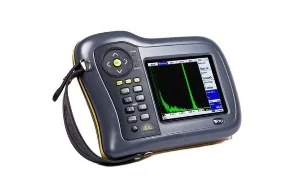

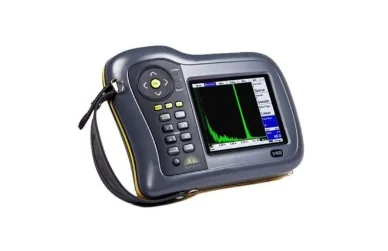

Our comprehensive range of portable ultrasonic flaw detectors provide the user with unrivalled flexibility and performance in the field of Non-Destructive Flaw detection.

Understanding Ultrasonic Flaw Detectors

Ultrasonic flaw detectors are vital instruments used in the non-destructive testing process. These flaw detectors are engineered to detect issues like cracks or faults within a material, without causing any damage to the material itself.

How Do Ultrasonic Flaw Detectors Work?

Flaw detectors work by sending high-frequency sound waves into the material. When these waves encounter a fault, they bounce back. This echo is then decoded by the flaw detector, yielding details about the type, size, and location of the fault.

Portable Flaw Detection

Our range of portable ultrasonic flaw detectors are lightweight and easy to carry, making them highly portable. This portability, combined with the exceptional performance of our flaw detectors, makes them perfect for fieldwork.

Flexible Testing Systems

A remarkable feature of our flaw detectors is their field upgradeability. This means you can perform updates onsite, reducing downtime and enhancing operational flexibility. This versatility makes the flaw detector an essential and user-friendly tool across many applications.

Sonatest: Powerful and End-User Focused Solutions

Our collection of flaw detectors, proudly manufactured by Sonatest, are robust. With the needs of the end-user at the heart of their design, these flaw detectors reliably deliver accurate results, playing a crucial role in ensuring safety and material integrity across different industries.