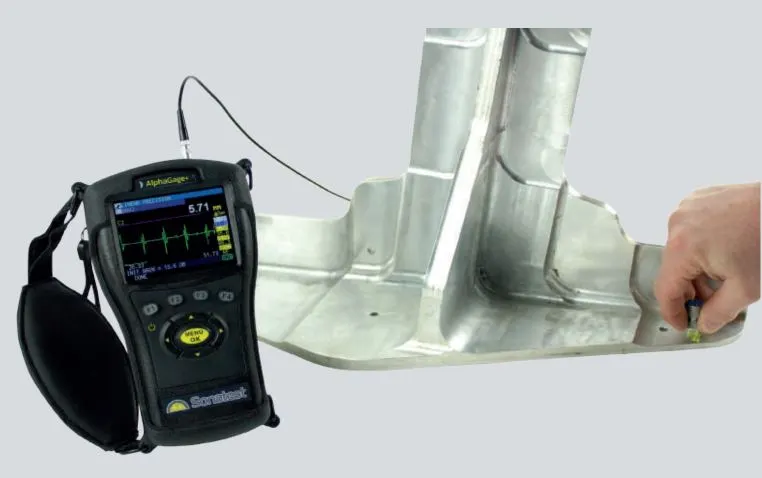

An ultrasonic thickness gauge is particularly useful for non-destructive thickness measurement when access is only possible from one side of the material, for example pipes or tanks. Thickness measurement can be performed on most common engineering materials, such as metal, plastic and glass.

Non-Destructive Thickness Gauging

An ultrasonic thickness gauge works on a similar principle to sonar, except at far higher frequencies and speed. A transmitter sends a short pulse of ultrasound into the material. The pulse is reflected as an echo from the opposite surface of the material, returning to a receiver. The thickness gauge analyses the length of time the pulse takes to return in order to calculate and then display the thickness. Non-destructive test equipment is used in many applications, especially in industry.

Many building, construction, manufacturing and operating industries have standards and regulations surrounding the appropriate and minimum allowable thickness of materials for use in specified applications. Gauges are used to accurately measure and check that material thicknesses are at an acceptable level thereby providing adequate protection and quality.

Thickness measurement is required for checking new equipment fabrications but also for in service items. Regular measurement of in service items can be used to predict corrosion/erosion rates and hence remaining available service life.